Global leader in home textiles

Steered by innovation leadership & strong research-led consumer focus.

capabilities from Design to Manufacturing from Supply chain to Analytics

Thought leader in Home,

highest in the industry

supplier to the USA, by Home Textiles Today (HTT)

Solution with Blockchain: 1st in the industry

distribution and reach with global retailers and marquee customers

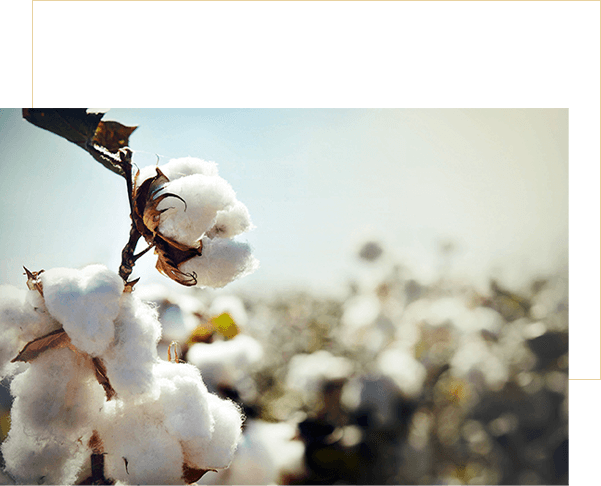

Weaving Sustainability revolution with

used for textile manufacturing

Keeping consumer wellbeing at the core, we provide smart, comprehensive solutions for a healthier, sustainable world, supported by our integrated facilities and 360° capabilities. As one of the globally leading home textile manufacturer companies in India for 35+ years, we are driven by our differentiation strategy based on Innovation, Branding & Sustainability.

As the leading textile company in India, we maintain the focus on the domestic market with sustainable textiles and on building a strong B2C presence while continuing to grow our export business.

We strive to redefine how the textile industry in India runs in a socially responsible & sustainable manner.

Know more

global leader in Home textiles

Towel & Sheet respectively sold in the US, made by Welspun

Revenues from Innovative products

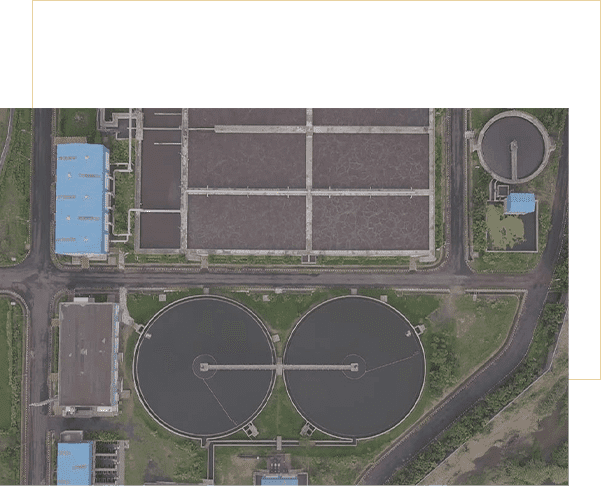

litres of Water Recycling capacity, per day

in 30,000+ workforce

Our brand spectrum continues to evolve

We strive to redefine how the textile business runs in a socially responsible & sustainable manner.

Know more